Friendly Flow Computer for all your industrial flow measurement needs

Whatever fluid you measure, your flow computer needs to be robust and reliable. You need proven technology that integrates with your existing equipment and provides easy access to your data.

UNIFLOW-200 gives you exactly that, and much more.

Let us show you how UNIFLOW-200 flow computers make your flow measurement straightforward, economic, and stress-free.

A flow computer built for the industry

UNIFLOW was originally designed for hydrocarbon gas and liquid flow measurement. The standard features of the instrument make it ideal for fiscal measurement and custody transfer. UNIFLOW-200 also excels as a cost effective flow computer for process applications.

Our flow computers are used by:

- Metrologists and process engineers who need undisputable flow measurement data

- Hydrocarbon producers that require robust and reliable metering solutions

- Industrial producers that are serious about process optimisation

- Flow meter manufacturers that need a reliable flow computer to integrate their products with

- Gas transmission system operators doing custody transfers and fiscal measurements

- Engineering companies designing redundant flow measurement systems

- Flow measurement professionals who need to work with several types of existing equipment

- System integrators who need heavy-duty solutions with a friendly price tag

- Energy professionals who want to keep tight account of energy consumption

Truly universal

UNIFLOW-200 supports virtually all fluids and we're yet to hear of an industry where our flow computers wouldn't fit.

Whether it’s gas & oil, pharmaceutical, power generation or heavy metal industry, UNIFLOW will meet your flow measurement needs every time.

See all supported fluids

| Hydrocarbons | natural gas, coke oven gas, blast furnace gas, crude oils, refined products, lubricating oil, NGL & LPG |

| Industrial gases | air, nitrogen, oxygen, argon, hydrogen, carbon-dioxide, carbon-monoxide, propane, ethylene, ammonium, general gases |

| Liquids other than water | ethanol, MTBE, ETBE, general liquids, liquid mixture |

| Water | Water, water steam, water-glycol mixture - energy flow (heat transfer) calculation |

Always reliable

UNIFLOW units are built for heavy industrial use, so we build them extremely reliable. They simply work year after year so your measurements are safe and there’s no need to worry about data loss.

Works with 8 + 4 meter runs

UNIFLOW allows you to work with data from up to 8 flow meters simultaneously, using just one flow computer. We keep your costs low and protect your bottom line.

400 days’ archive

Store 400 days of reports, access alarm and event logs remotely.

Look back to hourly measurements from more than a year any time. The archives are stored on non-volatile memory to make sure your data is always safe.

Friend of all flow meters

UNIFLOW works with your existing equipment and lets you work with the flow meters you choose. With a virtually endless possibility of data sources, you don’t need to worry about compatibility.

Pressure differential devices, ultrasonic meters, turbine and Vortex meters, mass flow meters, and many more are covered.

More about flow meter compatibility

UNIFLOW-200 can be configured to perform the flow calculation for a very wide range of flow meters. Besides the standard differential pressure devices (orifice plate, nozzle, Venturi tube according to ISO 5167) other devices such as Annubar, V-Cone, segmental orifice plate, or a flow meter with power characteristics (e.g. Parshall flumes) can also be configured.

Flow calibration data (flow coefficient vs. flow rate) can be entered for non-standard devices.

Turbine meters

For gas flow metering devices with pulse output (turbine meter, Vortex meter) dual pulse input is provided. The continuous comparison of the main and check pulse trains allows instant detection of turbine meter blade damage. Pulse integrity check according to ISO 6551 level B is provided for liquid turbine meters.

Ultrasonic meters

Ultrasonic meters can be connected to the flow computer via pulse input like a turbine meter. It is also possible to use the serial link to acquire the flow information from ultrasonic meters. The ultrasonic meter is inherently bidirectional and therefore the UNIFLOW-200 distinguishes the forward and reverse flows and displays and totalizes them in separate streams.

Error curve correction

Error curve correction is available for the flow calibrated flow meters. The error correction method can be - linear interpolation with up to 16 error curve points, or - polynomial interpolation with up to 6th power. The log(flow rate/viscosity) vs. K-factor error curve correction is also available for liquid turbine meters.

Friend of all fluid properties

UNIFLOW-200 lets you calculate all required properties of supported fluids. Natural gas, industrial gases, crude oil & refined products, water and steam - your pick.

More about fluid properties

Natural gas properties

- compression factor calculation according to AGA8 (edition 1985 and 1992) detailed and gross methods, AGA NX19, GOST 30319 (edition 1996 and 2015)

- heating value, relative density and base density calculation according to ISO 6976 (edition 1995 and 2015), AGA5, GPA 2172, GOST 30319

- dynamic viscosity calculation according to GOST 30319, GOST R 8.770

- isentropic exponent calculation according to ISO 20765-1, GOST 30319

- Joule-Thomson coefficient calculation according to ISO 20765-1, ISO TR 9464

- Speed of sound calculation according to ISO 20765-1, GOST 30319

Gas composition for the natural gas properties calculation can be:

- read on-line from a gas chromatograph,

- downloaded from a supervisory system, or

- set as fixed value

Industrial gas properties

Properties calculation for most popular industrial gases (air, nitrogen, oxygen, argon, carbon-dioxide, carbon-monoxide, hydrogen, propane, ammonium, ethylene, other gases) are included.

Crude oil & refined product properties

Crude oil, refined products, lubricating oil and NGL & LPG temperature and pressure volume correction factor calculation includes:

- ASTM D1250/API 2540 (1980) Tables 23, 24, 53, 54

- API MPMS Chapter 11.1 Tables 23, 24, 53, 54, 59, 60

- API MPMS Chapter 11.2.1, 11.2.1M and 11.2.2, 11.2.2M.

- GPA TP-27

Water and steam properties

Water and water steam properties are accurately calculated according to IAPWS-IF97 publication.

Ethanol properties

Ethanol properties are calculated according to OIML R22 recommendation. Revised formula by Bettin H., Spieweck F. is implemented.

Friend of all standards

Use our flow computers for custody transfers, CO2 emission calculations, gas volume conversions, and measure everything according to the latest international standards.

UNIFLOW gives you bulletproof measurement data you can safely rely on.

More about supported standards

The flow computer has the EC-type examination certificate from the Hungarian Trade Licensing Office (MKEH) according to the Directive 2004/22/EC (MID) as a gas volume conversion device.

The UNIFLOW-200 MFC is a gas volume electronic conversion device complying with EN 12405 and OIML R140.

The flow computer is OIML R117 compliant, certified for custody transfer measurement of liquids like crude oil and refined products.

The UNIFLOW-200 MFC is approved as Calculator for Dynamic measuring system for liquids other than water according to OIML R 117-1.

UNIFLOW-200 calculates the CO2 emission for gaseous and liquid fuels according to 2004/156/EC and IPCC 1996. The CO2 emission reporting is simplified to the reading of the appropriate counters from the flow computer at the end of a reporting period.

Friend of smart instruments

Connect smart transmitters through HART or Honeywell DE protocols, poll chromatographs for gas composition, read and display data (including meter status) from the latest ultrasonic flow meters.

Modbus and other protocols are built-in to make UNIFLOW compatible with any flow meter on the market.

What all of this means for you? No worries about compatibility, ever.

More about interfaces

The UNIFLOW-200 MFC is capable to receive flow rate, pressure, differential pressure and temperature signals from smart transmitters according to HART and Honeywell DE protocols, eliminating this way the uncertainty related to D/A and A/D conversion in the transmitter and in the flow computer.

The UNIFLOW-200 has built-in protocol for Sick, Instromet, Daniel, Siemens, Flexim, Krohne, Caldon and Panametrics ultrasonic meters.

UNIFLOW-200 is prepared to poll process gas chromatographs (Daniel, ABB, Yamatake, Yokogawa) for on-line gas composition data. It is also prepared for the on-line gas properties calculation, further improving the accuracy of the flow and energy content calculation.

UNIFLOW-200 is able to interface with flow metering devices (e.g. ultrasonic meter) via serial link. It allows not only the acquisition of flow information (uncorrected volume flow rate) digitally, but makes it possible to read and display the diagnostic information from the flow meters as well. There is no need to run special service software to check the ultrasonic meter; its correct operation (its “health status”) can be checked any time using the display of the flow computer.

User friendly & secure

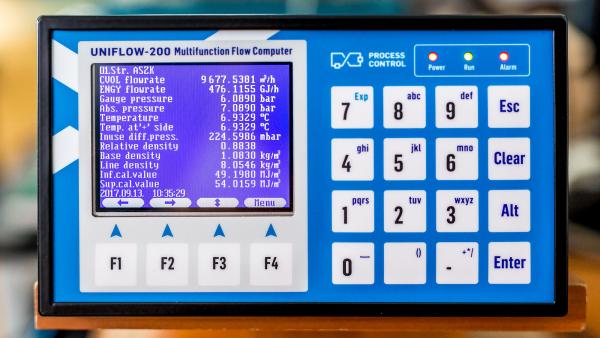

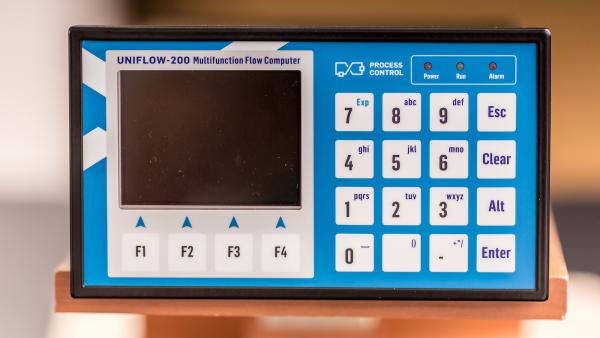

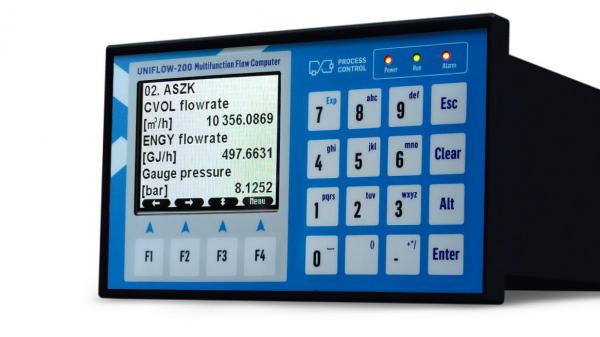

UNIFLOW units are simple to operate, no special training is required. Straightforward key navigation, multi-level menus, and a backlit LCD display provide easy data readings.

A password protected three-grade (guest, operator, engineer) access system is built in to prevent unauthorized change of important settings.

Your data is easy to access and impossible to mess with.

Future proof

UNIFLOW is a long-term investment. We continuously update firmware to implement updated and new measurement standards. This allows UNIFLOW units to serve extremely long which makes sure your investment budget is well spent.

3 years full warranty

We know our flow computers inside out and we know they are going to last.

Each UNIFLOW unit comes with 3 years full warranty. Our promise is that you’ll have absolutely zero repair and maintenance costs during the first 3 years.

Even after the warranty period we will provide you with replacement units in case you need to send your flow computer back to us.

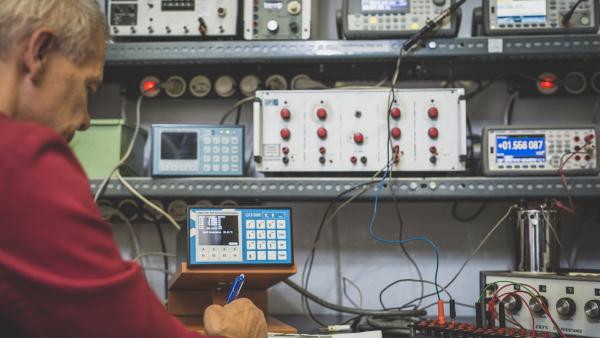

All units get thoroughly tested before being delivered.

Budget friendly

We offer a serious product for almost unserious prices.

Your flow computer investments costs can be as low as €600 per meter run. UNIFLOW offers a great price/value ratio that is really hard (if not impossible) to match for anyone on the market.

Ready to use

UNIFLOW-200 units are tested and calibrated before delivery.

On request, we're also happy to configure them to your use case. You tell us what and how you want to measure and get a flow computer ready to use.

OEM / White label solutions

Want to sell our flow computer with your logo on it? No problem. Get in touch to talk about OEM solutions.

Engineering hotline

Commissioning of your UNIFLOW-200 is made easy with free support from our engineers. We're here to help you set up.

Hands-on Support

Your problem is our problem, too.

All of our customers are long term customers. Inside and outside warranty time, we do everything to make sure UNIFLOW-200 units run smoothly.

Whether it's a failure you need to resolve quickly or new feature you want to implement, you can count on our expertise and hands-on approach.

You won't be waiting for weeks or months until something gets done, as it happens sometimes with big companies. We react in 24 hours to failure reports and other requests.

Convinced yet?

Don't just take our word for it. Request access to a live UNIFLOW-200 Flow Computer and try it out online.

What you can do with UNIFLOW-200

- Measure 8 fluid flows in closed conduits simultaneously

- Measure according to the current international standards and recommendations

- Calculate the physical properties of more than 30 fluids (gases, liquids and steam)

- Calculate properties for energy flow calculations

- Calculate CO2 emission

- Use data from a wide range of flow meters

- Measure custody transfers and provide fiscal measurements

- Save money on process applications

- Build redundant metering systems at a moderate cost

- Use 4 additional station totalizations

- Recall hourly metering data archives for 400 days

- Quickly implement new measuring methods and fluids on request

Need more details? Click here to see all facts & full specifications.

Photos

See how UNIFLOW-200 compares

We're proud to say UNIFLOW-200 does everything what the competitors do, and sometimes even more. See our comparison chart.

See comparison chart

| Model | FlowBoss S600 | UNIFLOW 200 | OMNI 6000 |

| Manufacturer | Emerson | Process Control | Omni |

| Application | |||

| Gas | x | x | x |

| Liquid | x | x | x |

| Prover | x | x | |

| Units | |||

| Imperial units | x | x | x |

| Metric units | x | x | x |

| Mount | |||

| Field | - | - | - |

| Panel | x | x | x |

| Meter Runs | |||

| Number of meter runs | 10 | 8 | 4 |

| IHM | |||

| Writing | x | x | x |

| Reading | x | x | x |

| Primary elements | |||

| Orifice | x | x | x |

| Nozzle | x | x | x |

| Venturi | x | x | x |

| Vortex | - | x | - |

| Turbine | x | x | x |

| Annubar | x | x | x |

| V-Cone | x | x | - |

| Ultrasonic meter | x | x | x |

| Calculations, density equation | |||

| ISO 5167 (orifice) | x | x | x |

| AGA 3 (orifice) | x | x | x |

| AGA 5 (heating value) | x | x | x |

| AGA 7 (turbine) | x | x | x |

| AGA 8 (compr. factor) | x | x | x |

| AGA 9 (ultrasonic) | - | x | - |

| AGA 10 (speed of sound) | x | x | x |

| AGA 11 (coriolis) | - | x | x |

| NX 19 (compr. factor) | x | x | x |

| ISO 6976 (energy) | x | x | x |

| API Chapter 11.1 (crude oil) | x | x | x |

| Slave support | |||

| Ultrasonic | x | x | x |

| Gas Chromatograph | x | x | x |

| Coriolis | x | x | x |

| Honeywell DE | - | x | x |

| Reports | |||

| Hourly | x | x | x |

| Daily | x | x | x |

| Monthly | x | x | x |

| Batch | x | x | x |

| Hour Detail | x | x | x |

| Day Detail | 400 | ||

| Month Detail | x | x | x |

| Calibration | x | x | x |

| Audit Trail | x | x | x |

| Alarm | x | x | x |

| I/O up to (Channel/Board) | |||

| Analog Input | 12 | 8 | 7 |

| Analog Output | 4 | 4 | 6 |

| Digital Input | 16 | 8 | 12 |

| Digital Output | 12 | 4 | 12 |

| RTD | 3 | 4 | 3 |

| Pulse inputs | 4 | 4 | 4 |

| Pulse outputs | 5 | 4 | 1 |

| Frequency (density) | 3 | 4 | 1 |

| Multivariable | - | 1 | - |

| Ports | |||

| RS232 | x | x | x |

| RS485 | x | x | x |

| Ethernet | x | x | x |

| USB | x | x | - |

| Modem | - | - | x |

| Serial Printer | x | x | - |

| Protocol | |||

| Modbus | x | x | x |

| Profibus | - | - | - |

| Foundation Fieldbus | - | - | |

| Hart | x | x | x |

| Power | |||

| VAC | - | 110/220 | 110/220 |

| VDC | 24 | 24 | 24 |

Get an Online Demo

Give it a try! Request access to a live UNIFLOW-200 Flow Computer and test it inside your web browser.

Used by all industries

We delivered more than 3000 flow computers to customers in various industries. National gas transmission system, nuclear power plant, pharmaceutical production, heavy metal and chemical industry - UNIFLOW covers all flow measurement needs, including yours.

Happy customers

Try It out!

Don't just take our word for it. Request access to a live UNIFLOW-200 Flow Computer and try it out online.

Have a chat first?

Not sure what you need yet? Get a free consultation from our specialists to see how we can help the delivery of your project.