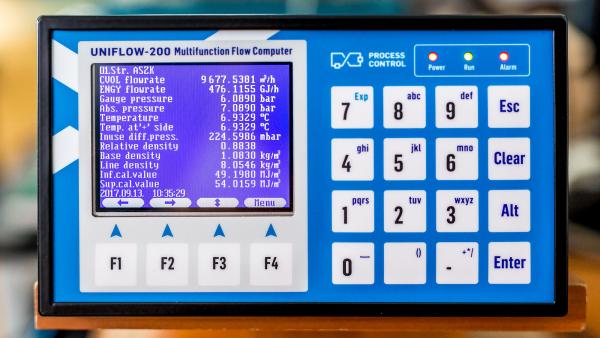

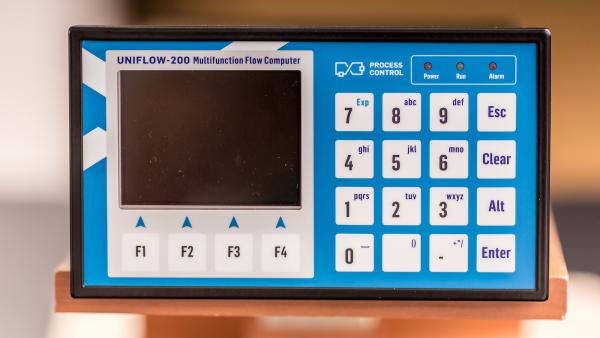

UNIFLOW-200 Flow Computer

The UNIFLOW-200 MFC (Multifunctional Flow Computer) is one of the most flexible flow computers in the world.

An ideal platform for even the most demanding applications that allows cost effective flow measurement without compromise. Whatever the fluid and the flow meter - UNIFLOW-200 calculates it all.

What you can do with UNIFLOW-200

- Measure 8 fluid flows in closed conduits simultaneously

- Measure according to the current international standards and recommendations

- Calculate the physical properties of more than 30 fluids (gases, liquids and steam)

- Calculate properties for energy flow calculations

- Calculate CO2 emission

- Use data from a wide range of flow meters

- Measure custody transfers and provide fiscal measurements

- Save money on process applications

- Build redundant metering systems at a moderate cost

- Use 4 additional station totalizations

- Recall hourly metering data archives for 400 days

- Quickly implement new measuring methods and fluids on request

Photos

The UNIFLOW-200 MFC was originally designed for hydrocarbon gas and liquid flow measurement. The standard features of the instrument make it ideal for fiscal measurement and custody transfer.

Besides custody transfers, UNIFLOW-200 is easily applicable as a cost effective flow computer for process applications. UNIFLOW-200 units are often used for process optimization purposes by our partners.

Measures all fluids

UNIFLOW-200 measures natural gas, all types of industrial gases, crude oil & refined products, water and steam.

See all supported fluids

| Hydrocarbons | natural gas, coke oven gas, blast furnace gas, crude oils, refined products, lubricating oil, NGL & LPG |

| Industrial gases | air, nitrogen, oxygen, argon, hydrogen, carbon-dioxide, carbon-monoxide, propane, ethylene, ammonium, general gases |

| Liquids other than water | ethanol, MTBE, ETBE, general liquids, liquid mixture |

| Water | Water, water steam, water-glycol mixture - energy flow (heat transfer) calculation |

Calculates all fluid properties

UNIFLOW-200 calculates all required properties of the supported fluids, natural gas, industrial gases, crude oil & refined products, water and steam.

More about fluid properties

Natural gas properties

- compression factor calculation according to AGA8 (edition 1985, 1992 and 2017) detailed and gross methods, AGA NX19, GOST 30319 (edition 1996 and 2015)

- heating value, relative density and base density calculation according to ISO 6976 (edition 1995 and 2016), AGA5, GPA 2172, GOST 30319

- dynamic viscosity calculation according to GOST 30319, GOST R 8.770

- isentropic exponent calculation according to AGA8, ISO 20765-1, GOST 30319

- Joule-Thomson coefficient calculation according to AGA8, ISO 20765-1, ISO TR 9464

- Speed of sound calculation according to AGA8, ISO 20765-1, GOST 30319

Gas composition for the natural gas properties calculation can be:

- read on-line from a gas chromatograph,

- downloaded from a supervisory system, or

- set as fixed value

Industrial gas properties

Properties calculation for most popular industrial gases (air, nitrogen, oxygen, argon, carbon-dioxide, carbon-monoxide, hydrogen, propane, ammonium, ethylene, other gases) are included.

Crude oil & refined product properties

Crude oil, refined products, lubricating oil and NGL & LPG temperature and pressure volume correction factor calculation includes:

- ASTM D1250/API 2540 (1980) Tables 23, 24, 53, 54

- API MPMS Chapter 11.1 Tables 23, 24, 53, 54, 59, 60

- API MPMS Chapter 11.2.1, 11.2.1M and 11.2.2, 11.2.2M.

- GPA TP-27

Water and steam properties

Water and water steam properties are accurately calculated according to IAPWS-IF97 publication.

Ethanol properties

Ethanol properties are calculated according to OIML R22 recommendation. Revised formula by Bettin H., Spieweck F. is implemented.

Standard Compliant measurements

UNIFLOW-200 conforms to all widely used standards as a gas volume conversion device, as a custody transfer measurement device and also as a CO2 emission calculator.

More about supported standards

The flow computer has the EC-type examination certificate from the Hungarian Trade Licensing Office (MKEH) according to the Directive 2014/32/EC (MID) as a gas volume conversion device.

The UNIFLOW-200 MFC is a gas volume electronic conversion device complying with EN 12405 and OIML R140.

The flow computer is OIML R117 compliant, certified for custody transfer measurement of liquids like crude oil and refined products.

The UNIFLOW-200 MFC is approved as Calculator for Dynamic measuring system for liquids other than water according to OIML R 117-1.

UNIFLOW-200 calculates the CO2 emission for gaseous and liquid fuels according to 2004/156/EC and IPCC 1996. The CO2 emission reporting is simplified to the reading of the appropriate counters from the flow computer at the end of a reporting period.

Try it out!

Request access to a live UNIFLOW-200 Flow Computer and try it out online.

Works with any flow meter

Pressure differential devices, ultrasonic meters, turbine and Vortex meters, mass flow meters, and many more...

More about flow meter compatibility

UNIFLOW-200 can be configured to perform the flow calculation for a very wide range of flow meters. Besides the standard differential pressure devices (orifice plate, nozzle, Venturi tube according to ISO 5167) other devices such as Annubar, V-Cone, segmental orifice plate, or a flow meter with power characteristics (e.g. Parshall flumes) can also be configured.

Flow calibration data (flow coefficient vs. flow rate) can be entered for non-standard devices.

Turbine meters

For gas flow metering devices with pulse output (turbine meter, Vortex meter) dual pulse input is provided. The continuous comparison of the main and check pulse trains allows instant detection of turbine meter blade damage. Pulse integrity check according to ISO 6551 level B is provided for liquid turbine meters.

Ultrasonic meters

Ultrasonic meters can be connected to the flow computer via pulse input like a turbine meter. It is also possible to use the serial link to acquire the flow information from ultrasonic meters. The ultrasonic meter is inherently bidirectional and therefore the UNIFLOW-200 distinguishes the forward and reverse flows and displays and totalizes them in separate streams.

Error curve correction

Error curve correction is available for the flow calibrated flow meters. The error correction method can be - linear interpolation with up to 16 error curve points, or - polynomial interpolation with up to 6th power. The log(flow rate/viscosity) vs. K-factor error curve correction is also available for liquid turbine meters.

Connects reliably to anything

Galvanically isolated I/O points.

Trouble-free, no potentiometers, no batteries.

Input and output channels are software calibrated.

The UNIFLOW-200 MFC can accommodate up to 5 I/O boards. Different combinations of analog, PRT, pulse and digital inputs, analog, pulse and digital outputs make the UNIFLOW-200 MFC suitable to solve any flow measurement problem.

More about inputs & outputs

The input and output channel assignment is freely configurable. Different meter runs can share the signal output of the same transmitter. Several output channels can be assigned to the same variable (e.g. flow rate), if different interfacing systems require independent output channels.

All input and output channels are galvanically isolated and protected against overvoltage and miswiring (short circuit and overload). No earthing problem in the current input loops.

Resistance thermometers are connected to RTD inputs using the 4-wire connection method. In case of individually calibrated sensors the flow computer converts the measured resistance to temperature using the Calendar Van Dusen A, B, C and R0 constants.

High frequency inputs can receive pulse or frequency signals from flow meters. They can be configured for density transducers, too. The input signal level is software selectable from NAMUR, active 5 V, active 15 V or open collector.

Digital inputs can be used to signal the status of any dual state device, e.g. on/off valves. It also accepts low frequency (max. 50 Hz) pulse signals from flow meters (e.g. positive displacement meters).

Digital outputs can be configured as:

- pulse output representing flow totals,

- alarm output signaling high or low limit of any input channel or flow rate,

- control output to open or close valves for example,

- repeat the change of state of any digital input, or

- time base.

The NO or NC state of the digital output is selectable.

Smart interfaces for smart instruments

UNIFLOW-200 supports HART transmitter protocols and has serial interfaces for gas chromatographs and ultrasonic flow meters (Modbus, Instromet US meter protocols).

More about interfaces

The UNIFLOW-200 MFC is capable to receive flow rate, pressure, differential pressure and temperature signals from smart transmitters according to HART protocols, eliminating this way the uncertainty related to D/A and A/D conversion in the transmitter and in the flow computer.

The UNIFLOW-200 has built-in protocol for Sick, Instromet, Daniel, Siemens, Flexim, Krohne, Caldon and Panametrics ultrasonic meters.

UNIFLOW-200 is prepared to poll process gas chromatographs (Daniel, ABB, Yamatake, Yokogawa) for on-line gas composition data. It is also prepared for the on-line gas properties calculation, further improving the accuracy of the flow and energy content calculation.

UNIFLOW-200 is able to interface with flow metering devices (e.g. ultrasonic meter) via serial link. It allows not only the acquisition of flow information (uncorrected volume flow rate) digitally, but makes it possible to read and display the diagnostic information from the flow meters as well. There is no need to run special service software to check the ultrasonic meter; its correct operation (its “health status”) can be checked any time using the display of the flow computer.

Extensive reporting & data archiving

Store 400 days of reports, access alarm and event logs remotely.

Hourly, shift, daily, multi-day and monthly reports are stored in the non volatile memory. Besides the periodic totals, average, minimum and maximum values of the inputs and calculated parameters are stored in the reports.

More about reporting

Archived data can be called up on the display, can be printed out using the serial link, can be copied to the pendrive via USB port and can be transferred by means of the U200ToolBox software.

Alarms are stored with timestamps in the alarm log file.

Any modification of the flow computer parameters is recorded in the event log file.

Gas composition data downloaded from a supervisory system or read from a gas chromatograph are recorded in the log file as well.

The alarm, event and download archives can be called up on the display, can be copied to the pendrive and can be uploaded to a PC for further investigation. The storage capacity allows archiving metering data, alarms and event log for 400 days.

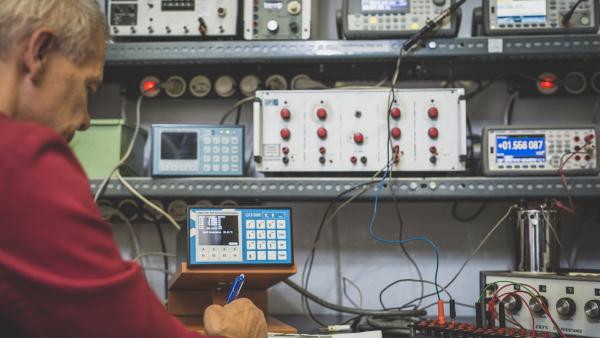

Top-notch support

We pride ourselves in providing great customer support.

All of our customers are long term customers. Inside and outside warranty time, we do everything to make sure UNIFLOW-200 units run smoothly.

Whether it's a failure you need to resolve quickly or new feature you want to implement, you can count on our expertise and hands-on approach.

You won't be waiting for weeks or months until something gets done, as it happens sometimes with big companies. We react in 24 hours to failure reports and other requests.

3 years full warranty

UNIFLOW-200 is built to last.

We build sturdy machines to industrial standards. UNIFLOW-200 is a mature product that proved reliable on thousands of locations around the world.

We guarantee that you won't have any repair or maintenance costs during the first 3 years.

Even after the warranty period we can provide you with replacement units in case you need to send your flow computer back to us.

All units get thoroughly tested before being delivered.

Extremely cost effective

Save lots of money when building metering stations and metering systems.

Unmatched flexibility, quality, performance, and accuracy come with a very friendly price tag. Flow computer investment costs for one meter run can be as low as €600.

Calibrated & preconfigured to your application

We deliver your flow computers calibrated at no extra cost and we're happy to configure them to your use case on request.

Preconfiguration is subject to supplied data about the use case. You tell us what and how you want to measure and get a flow computer ready to use.

Try it out!

Request access to a live UNIFLOW-200 Flow Computer and try it out online.

See how UNIFLOW-200 compares

We're proud to say UNIFLOW-200 does everything what the competitors do, and sometimes even more. See our comparison chart.

See comparison chart

| Model | FloBoss S600 | UNIFLOW 200 | OMNI 6000 |

| Manufacturer | Emerson | Process Control | Omni |

| Application | |||

| Gas | x | x | x |

| Liquid | x | x | x |

| Prover | x | coming soon | x |

| Units | |||

| Imperial units | x | x | x |

| Metric units | x | x | x |

| Mount | |||

| Field | - | - | - |

| Panel | x | x | x |

| Meter Runs | |||

| Number of meter runs | 10 | 8 | 4 |

| IHM | |||

| Writing | x | x | x |

| Reading | x | x | x |

| Primary elements | |||

| Orifice | x | x | x |

| Nozzle | x | x | x |

| Venturi | x | x | x |

| Vortex | - | x | - |

| Turbine | x | x | x |

| Annubar | x | x | x |

| V-Cone | x | x | - |

| Ultrasonic meter | x | x | x |

| Coriolis meter | x | x | x |

| Calculations, density equation | |||

| ISO 5167 (orifice) | x | x | x |

| AGA 3 (orifice) | x | x | x |

| AGA 5 (heating value) | x | x | x |

| AGA 7 (turbine) | x | x | x |

| AGA 8 (compr. factor) | x | x | x |

| AGA 9 (ultrasonic) | - | x | - |

| AGA 10 (speed of sound) | x | x | x |

| AGA 11 (coriolis) | - | x | x |

| NX 19 (compr. factor) | x | x | x |

| ISO 6976 (energy) | x | x | x |

| API Chapter 11.1 (crude oil) | x | x | x |

| Slave support | |||

| Ultrasonic | x | x | x |

| Gas Chromatograph | x | x | x |

| Coriolis | x | x | x |

| Reports | |||

| Hourly | x | x | x |

| Daily | x | x | x |

| Monthly | x | x | x |

| Batch | x | x | x |

| Hour Detail | x | x | x |

| Day Detail | 400 | ||

| Month Detail | x | x | x |

| Calibration | x | x | x |

| Audit Trail | x | x | x |

| Alarm | x | x | x |

| I/O up to (Channel/Board) | |||

| Analog Input | 12 | 8 | 7 |

| Analog Output | 4 | 4 | 6 |

| Digital Input | 16 | 8 | 12 |

| Digital Output | 12 | 4 | 12 |

| RTD | 3 | 4 | 3 |

| Pulse inputs | 4 | 4 | 4 |

| Pulse outputs | 5 | 4 | 1 |

| Frequency (density) | 3 | 4 | 1 |

| Multivariable | - | 1 | - |

| Ports | |||

| RS232 | x | x | x |

| RS485 | x | x | x |

| Ethernet | x | x | x |

| USB | x | x | - |

| Modem | - | - | x |

| Serial Printer | x | x | - |

| Protocol | |||

| Modbus | x | x | x |

| Profibus | - | - | - |

| Foundation Fieldbus | - | - | |

| Hart | x | x | x |

| Power | |||

| VAC | - | 110/220 | 110/220 |

| VDC | 24 | 24 | 24 |

Inputs & outputs

Analog inputs

| Input range | 0/4-20 mA * |

| Accuracy | +/- 0,02 % |

| Input voltage drop | 5 V max. |

| Potential diff. among inputs | 50 V max. |

4-wire RTD inputs

| Sensor type Pt100 ** | standard or individually calibrated |

| Accuracy | +/- 0,1 °C |

| Maximum loop resistance | 500 ohms |

Pulse-frequency inputs (including NAMUR)

Signal processing without loss of pulses.

Signal processing without loss of pulses.

| Frequency range | 0 ... 10 000 Hz |

| Input signal level | 2 V …10 V |

| Signal form | square, unipolar |

| Inaccuracy of frequency measurement | 0,001 % max. |

Digital inputs

Potential-free contacts, open collector (transistor) and 24 VDC inputs can be accepted and used as

- static inputs, or

- pulse inputs (frequency: 50 Hz max., 50 % fill in ratio)

without any further activity required from the user.

Potential-free inputs are supplied with power from the circuit board (15 VDC, 6,8 kohm)

Analog outputs

Output channels with individual galvanic isolation

Output channels with individual galvanic isolation

| Output range | 0/4-20 mA * |

| Resolution | 12 bits |

| Load | 500 ohm max. |

Digital outputs

Galvanically isolated open collector (transistor), overvoltage- and overcurrent-protected outputs.

Galvanically isolated open collector (transistor), overvoltage- and overcurrent-protected outputs.

| Load | 100 mA, 40 Vdc max. |

Field bus inputs

HART point to point or multidrop connections using HART protocol complete with 24 Vdc power supply

Digital communication

RS232/RS422/RS485*

| Baud rate | 1200 … 38400 bit/sec* |

| Protocol | Modbus (RTU, ASCII) |

| Length of cable | RS232: 15m max. |

| RS485/422: 1200m max. |

10 / 100 Ethernet

| Connector | RJ 45 |

| Protocol | Modbus TCP |

USB

| For saving data to USB drive. | |

| USB version support | USB 1.1 and above |

Operator Panel

3,5” color TFT LCD display with selectable background color. Foil protected membrane keyboard.

Uncertainty

Uncertainty of the calculated flow rates and totals:

- Less than +/- 0.05 % under reference conditions.

- Less than +/- 0.1 % in the 0 - 50 °C temperature range.

Environment

| Operating temperature | -10 ... 50°C |

| Operating humidity | 0 ... 90 %. non-condensing |

| Storage temperature | -25 ... 70°C |

Power requirements

| Power inputs | 230 (110) Vac +10 %, -15 %, 50-60 Hz |

| 24 Vdc (20 ... 35 V) | |

| Power consumption | 25W max. |

| Transmitter power | 1 x 24 Vdc, 200 mA max. |

Dimensions

| Panel cut-out | 186mm W x 91mm H |

| Case depth | 260mm |

| Front panel | 195mm W x 110mm H |

| Weight | 4,3 kg |

Compliances and certificates

- EN 12405

- OIML R117

- OIML R140

- EC-type certificate

- Available with European CE Mark

Standards used in calculations

| Flow meter standards | ISO 5167 (1991, 1998, 2003), EN 12405 (2005, 2018, 2021), AGA 3 (1990, 2012), AGA 7 (1996, 2006), AGA 9 (1998, 2022), GOST 8.563 (1997), GOST 8.586 (2005) |

| Gas standards | AGA 8 (1985, 1992, 2017), AGA NX19, ISO 20765-1, ISO 6976 (1995, 2016), AGA 5, GPA 2172 (2009, 2014), GOST 30319 (1996, 2015) |

| Oil standards | ASTM 2540, API Chapter 11.1, API 11.2.1, API 11.2.1M, API 11.2.2, API 11.2.2M, GPA TP-27, STO Gazprom 5.9 |

| Water, steam | IAPWS-IF97 |

| Ethanol | OIML R22 (revised formula by Bettin H., Spieweck F.) |

If you need to support any other standards, please let us know.

I/O Modules

| ANI8 | 8 ch 4-20 mA |

| PT4 | 4 ch Pt100 ** |

| ANI4PT2 | 4 ch 4-20 mA, 2 ch Pt100 ** |

| PDIO484 | 4 ch pulse input, 8 ch digital input 4 ch digital output (obsolete replaced by PITC4641) |

| PITC4641 | 4 ch pulse input, 6 ch digital input 4 ch digital output, 1 ch pulse output |

| AODIO484 | 4 ch 4-20 mA output, 8 ch digital input 4 ch digital output |

| HTI4x15 | 4 loops to scan 15 HART PV/loop (multidrop) or |

| 4 pcs HART transmitters (point to point), using HART protocol |

Supported flow meters

Orifice, Nozzle, Venturi tube, V-Cone, Annubar, Vortex, Turbine, Positive displacement, Ultrasonic, Coriolis.

Supported fluids

| Hydrocarbons | natural gas, coke oven gas, blast furnace gas, crude oils, refined products, lubricating oil, NGL & LPG |

| Industrial gases | air, nitrogen, oxygen, hydrogen, argon, carbon-dioxide, carbon-monoxide, ethylene, ammonium, propane, general gase |

| Liquids other than water | ethanol, MTBE, ETBE, general liquids, two components liquid mixture |

| Water | water, water steam, water-glycol mixture - energy flow (heat transfer) calculation |

Explanations

* parameter selectable

** optionally Pt500 or Pt1000 is also possible

*** one UNIFLOW-200 MFC can accommodate up to 5 I/O boards in any combination

Try it out!

Request access to a live UNIFLOW-200 Flow Computer and try it out online.